Foundry work has always been a major player in the Illinois industrial sector. While the state is renowned for its manufacturing industry as a whole, casting is particularly vital – both as a service to end customers, and in support of other Illinois manufacturers. That’s why the Tazewell foundry specializes in aluminum sand casting services […] Read More

News and Articles

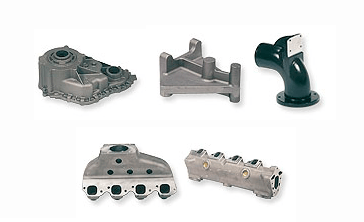

When many people think of industrial castings, what comes to mind is large machinery components and huge iron parts. However, we also use the sand casting process for many smaller, more common types of products. Capable of producing everything from run-of-the-mill pipes and fittings, valves and pump parts, to some of the most commonly used […] Read More

There are a lot of different methods for manufacturing custom metal castings, with sand casting being one of the most common processes. Using sand cores provides some unique advantages compared to using metal cores in die casting, or wax cores in investment casting – two of the most common competing services. Perhaps the most notable […] Read More

Sand casting is one of the industry’s most widely used casting processes because it’s versatile, cost-effective, and suitable for producing both small and large components alike. The basic process involves creating a custom mold out of sand which forms the unique internal features, shapes, and cavities within the casting. It’s a relatively quick and economical […] Read More