Sand casting is one of the industry’s most widely used casting processes because it’s versatile, cost-effective, and suitable for producing both small and large components alike.

The basic process involves creating a custom mold out of sand which forms the unique internal features, shapes, and cavities within the casting. It’s a relatively quick and economical tooling process in the realm of industrial manufacturing.

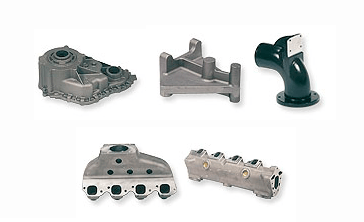

That’s why the Tazewell foundry specializes in aluminum sand casting services engineered around our customers’ unique requirements and specifications. We’ve refined our casting processes to accommodate complex parts of virtually all shapes and sizes. Plus, with our integrated CNC machine shop, we can take customization and complexity even further with custom machined castings.

Quality Sand Castings Manufactured at Tazewell

Our company has been in the business of manufacturing quality rough and machined castings since 1945. As you can imagine, over the decades we’ve manufactured unique products for a wide range of industrial applications.

A list of our common products alone should give you some idea of the versatility of sand casting services:

- Air transfer pipes

- Cast iron covers

- Explosion-proof electrical boxes and covers

- Industrial fuel manifolds

- Industrial gearbox housings

- Water-jacketed risers

- Machine oil pans

Below, we take a deeper dive into many of the common industrial uses and specific product applications for sand casting today.

Sand Casting Services: Common Industrial Uses and Product Applications

Construction Equipment and Architectural Castings

From industrial jobsite equipment to architectural castings, the modern construction sector finds many uses for sand cast components:

- Construction machinery parts

- Door furniture

- Decorative end pieces for aluminum extrusions

- Decorative metal art

- Jobsite equipment and installations

Industrial Castings and Factory Equipment

From critical machinery parts to safety covers, cases and boxes, custom castings are found throughout the modern factory floor:

- Air compressor pistons and parts

- Cast blowers and impellers

- Explosion-proof electrical covers and boxes

- Heavy machinery parts

- Housings for industrial electronics

- Industrial bearing and bushing components

- Industrial pistons and bump bodies

- Industrial valves and fittings

Sand Casting for the Oil, Gas, and Energy Industry

Out in the oilfield, in gas processing, and throughout the wind sector, cast components are critical to some of the energy industry’s most state-of-the-art systems:

- Cast valve bodies in oil pipes

- Explosion-proof electrical boxes for power plants

- Heavy machinery for oil and gas extraction

- Oilfield installation equipment

- Pistons, pump bodies, and various hydraulic equipment

- Power generator parts

- Tanks for gas/oil storage and transport

- Turbine components

Quality American Foundry Services Since 1945

No matter your industry or product application, Tazewell Machine Works provides exceptional American manufacturing for custom castings – rough or machined, built to your exact specifications. Our products are backed by a robust ISO 9001:2015 certified quality control system and over 75 years of excellence delivered from our foundry right here in Pekin, Illinois.